Introduction :

Capsule are a popular dosage form for medications and dietary supplements, offering a convenient and effective way to deliver active ingredients to the body. In this post, we’ll explore the world of capsule, including their benefits, types, and uses.

Table of Contents

What are Capsules?

Capsule are small, soluble containers made of gelatin or other materials that enclose a specific amount of active ingredient. They are designed to be taken orally, dissolving in the stomach or intestines to release the active ingredient.

Benefits of Capsule

Capsule offer several benefits, including:

- Convenience: Easy to take and transport

- Precise dosing: Allows for precise control over the amount of active ingredient delivered

- Flexibility: Can be formulated to release the active ingredient quickly or over an extended period

- Taste masking: Can mask unpleasant tastes and odors

- Protection: Protects the active ingredient from light, moisture, and oxygen

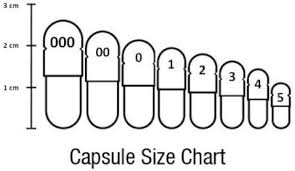

Types of Capsules

There are several types of capsule, including:

- Hard gelatin capsule: Made of gelatin and used for dry powders or granules

- Soft gelatin capsule: Made of gelatin and used for liquids or semi-solids

- Vegetarian capsule: Made from plant-based materials, suitable for vegetarians and vegans

- Enteric-coated capsule: Designed to resist stomach acid and release the active ingredient in the intestines

- Sustained-release capsuls: Designed to release the active ingredient over an extended period

Uses of Capsules

Capsules are used for a wide range of applications, including:

- Pharmaceuticals: Delivering medications for various health conditions

- Dietary supplements: Providing essential vitamins, minerals, and nutrients

- Nutraceuticals: Delivering health-promoting ingredients

- Vitamins and minerals: Delivering essential nutrients

- Herbal supplements: Delivering herbal extracts and botanicals

Manufacturing Process

The manufacturing process for capsule involves several steps, including:

- Formulation: Selecting the active ingredient and excipients

- Filling: Filling the capsule with the formulated mixture

- Sealing: Sealing the capsule to prevent leakage

- Quality control: Ensuring the capsule meet quality standards

- Packaging: Packaging the capsule for distribution

Quality Control

Quality control is critical in capsule manufacturing, ensuring that the capsule meet standards for:

- Content uniformity: Ensuring the active ingredient is evenly distributed

- Dissolution: Ensuring the capsule dissolves as intended

- Stability: Ensuring the capsule remains stable over time

- Purity: Ensuring the capsule is free from contaminants

Challenges in Capsule Manufacturing

Capsule manufacturing can be challenging, with issues such as:

- Fill weight variation: Ensuring consistent fill weights

- Capsule shell quality: Ensuring the capsule shell is of high quality

- Active ingredient stability: Ensuring the active ingredient remains stable

- Regulatory compliance: Ensuring compliance with regulatory standards

Regulatory Requirements

Capsule are subject to regulatory requirements, including:

- GMP: Good Manufacturing Practice regulations

- USP/NF: United States Pharmacopeia/National Formulary standards

- EP: European Pharmacopoeia standards

- JP: Japanese Pharmacopoeia standards

Future of Capsules

The future of capsule is exciting, with advances in technology and materials science enabling the development of:

- New materials: New materials for capsule shells, such as plant-based materials

- Novel delivery systems: New delivery systems that improve bioavailability and efficacy

- Personalized medicine: Tailoring capsules to individual patient needs

Conclusion

Capsules are a versatile and effective dosage form, offering many benefits for patients and manufacturers. By understanding the different types of capsules, their benefits, and the manufacturing process, we can appreciate the importance of capsules in the pharmaceutical and dietary supplement industries.

Whether you’re a healthcare professional, patient, or manufacturer, capsules are an essential part of many treatment regimens. By staying informed about capsules, we can ensure the safe and effective use of these dosage forms.

References

- United States Pharmacopeia/National Formulary: Standards for capsule quality and performance

- European Pharmacopoeia: Standards for capsule quality and performance

- Japanese Pharmacopoeia: Standards for capsule quality and performance

- Good Manufacturing Practice: Regulations for capsule manufacturing

Additional Resources

- manufacturing guides: Guides for capsule manufacturers

- Regulatory guidelines: Guidelines for regulatory compliance

- Research articles: Articles on capsule technology and innovation

By following the guidelines and regulations, manufacturers can ensure the production of high-quality capsules that meet patient needs and improve treatment outcomes.